Quality Assurance

We strive to provide the most accurate products and deliver them in the most efficient way. We have full traceability of our products and raw material right from the very first stage of procurement. Our team follows best practices all along the manufacturing and distribution processes and we aim to be highly productive

We are confident of our products and offer in house inspection reports in compliance with all international standards. We fully support 3rd Party Inspection and provide our total cooperation to your hired personnel.

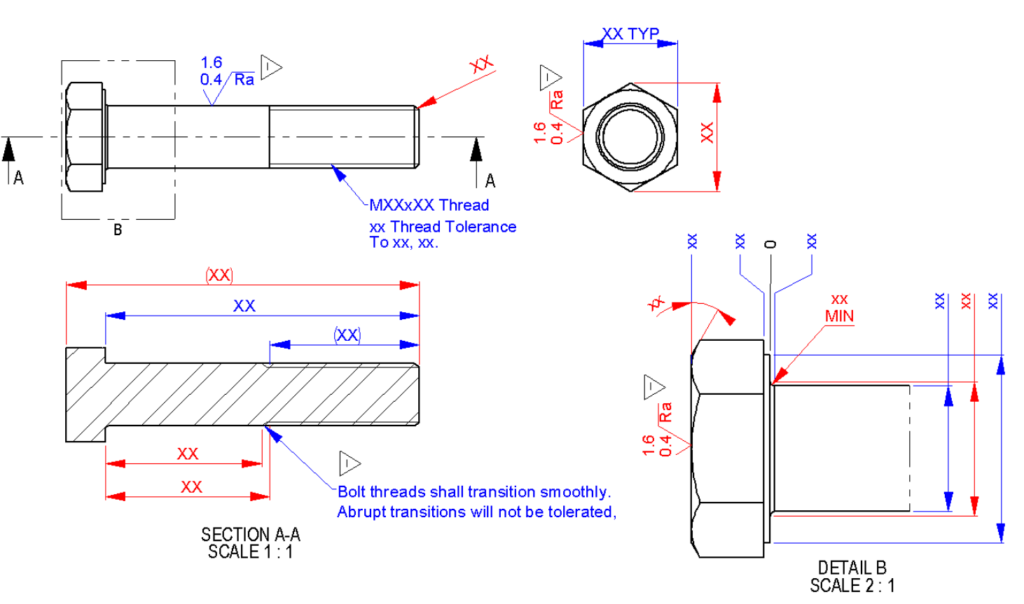

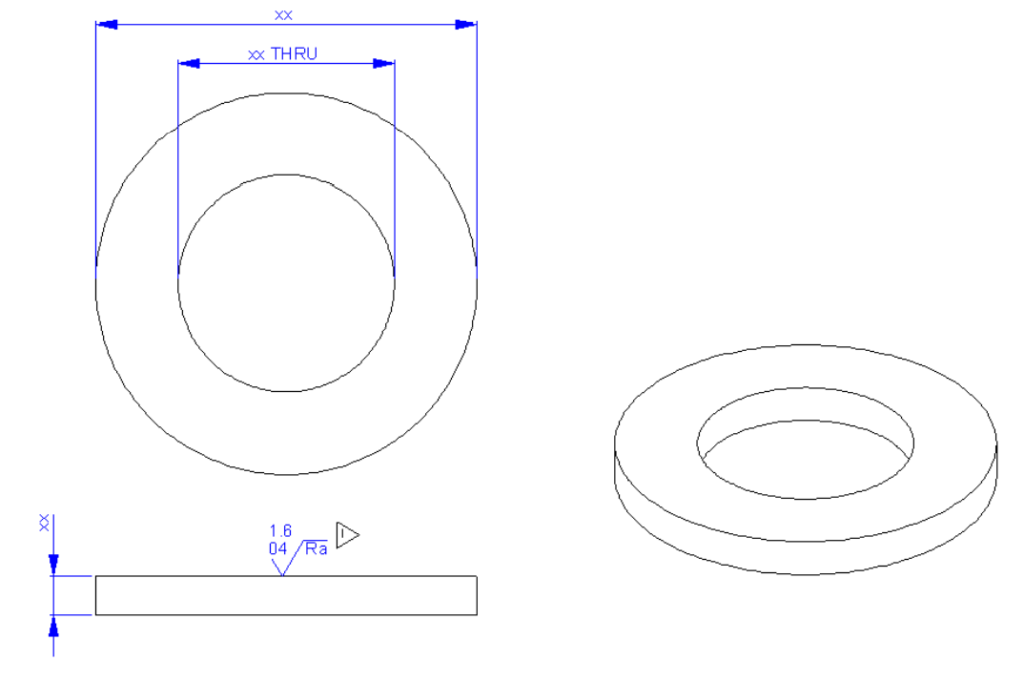

- All fasteners will be manufactured to a general tolerance of EN ISO 2786-mK, unless stated otherwise in the ISO/DIN (or equivalent) standards.

- All non-threaded component features shall have a general surface finish better than 1.6 Ra max

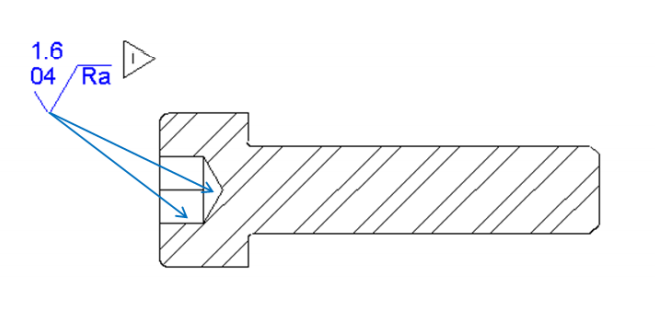

- Bolt threads shall transition smoothly into bolt shanks, (where applicable). Abrupt transitions will not be tolerated. If in doubt contact fas10(Fasten) for clarification.

- All bolt heads shall have an under head fillet radius and washer face as defined by the selected ISO/DIN fastener shape standard.

- The internal head features of socket head bolts, shall have a have a general surface finish better than 1.6 Ra max (before coating)

- Annotations with a

symbol are specific fas10(Fasten) requirements, refer to Figure 1, Figure 2, Figure 3 and Figure 4.

symbol are specific fas10(Fasten) requirements, refer to Figure 1, Figure 2, Figure 3 and Figure 4. - First article inspection dimensions are shown in red and blue. All dimensions specified in the standards are before coating application, (where applicable).

- Production batch inspection dimensions are shown in blue. All dimensions specified in the standards are before coating application, (where applicable).

Reports we provide with the order :

- Certificate of Conformity

- MTC in accordance with BS EN 10204 2.1, 2.2, 3.1

- MTC in accordance with BS EN 10204 3.2 Third Party Inspected

- Raw Material Mill Test Reports

- Dimensional Reports

- Gauge Test Reports

- Heat Treatment Charts

- NABL Approved Lab Test Reports

Additional Tests on Request :

- Spectro Analysis

- Chemical Analysis

- Ultrasonic Examination

- Salt Spray Test

- Liquid Penetration Test

- Dye Penetrant Test

- Magnetic Particle Examination

- Magnetic Particle Inspection

- Tensile Test

- Impact Test

- Creep Rupture Test

- Stress Rupture Test

- IGC Practice A, C, E (Microstructure)

- Macro test for Grain Flow

Packing

Male Thread protection:

- Plastic netting, (or similar).

- Material: Low-Density Polyethylene, (or similar).

Female Thread protection:

- Centre pull plastic plugs, (or similar).

- Material: Low-Density Polyethylene, (or similar).

TESTING FACILITIES

- Dye Penetrant Test (DP Test)

- Micro Test

- Intergranular Corrosion (IGC) Test

- Hardness Test

- Flaring Test

- Chemical Analysis – Spectro Analysis