Inconel 718 Fasteners

AISI Inconel 718 Fasteners, ASTM B637 Inconel 718 Plain Washer, ASME SB637 Grade 718 Hex Bolt, Inconel 718 Nut, UNS N07718 Threaded Rod, DIN 2.4668 Fasteners, Werkstoff Nr. 2.4668 Heavy Hex Bolt.

The nickel alloy known as Inconel 718 Fasteners, sometimes known as Alloy 718 or Hardenable Inconel, is the grade that is utilised the most frequently. Even when subjected to extremely high temperatures, the alloy retains a high level of strength thanks to the precipitation hardening process and the principal component of nickel and chromium. these free chemicals tend to build on the walls or surfaces of equipment, which can lead to cracks caused by stress. Because these compounds do not affect bolts made to ASTM B637 UNS N07718, these bolts are utilised in the processing of natural gas and in down-hole oil shafts and wellhead parts.

UNS N07718 bolt is utilised in the aerospace sector for applications like gas turbine engines, liquid oxygen turbo-pumps, and airframe components. These alloy 718 fasteners have excellent performance both in cryogenically low and very high temperatures. Even when subjected to temperatures that are extremely high or low, the strength of these Inconel 718 washers does not suffer. Cryogenic tanks make use of alloy 718 bolts because of their superior During the processing of natural gas, the machinery utilised is subjected to pollutants such as hydrogen sulphide (H2S) and carbon dioxide (CO2). When these contaminants mix with water, they produce free chemicals such as sulphur or carbonic acid, which are harmful to the environment—performance in both the mechanical and physical spheres in icy environments.

About Inconel 718 Fasteners

Werkstoff Nr. 2.4668 U Bolt, AISI Inconel 718 Hex Nut, ASME SB637 Grade 718 Stud Bolt, ASTM B637 Inconel 718 Threaded Rod, UNS N07718 Spring Washer, DIN 2.4668 Heavy Hex Nut, Inconel 718 Bolt.

Because nickel was added to the alloy that makes up Inconel 718, the screws made from this material offer extreme resistance to corrosion in facilities that process chemicals. AISI Inconel 718 Hex Nuts are also utilised in high-temperature applications, including steam generators, gas turbines, rocket motors, spacecraft, pumps, tools, and pressurised water reactors in nuclear power plants. Inconel 718 hex bolts are nearly twice as robust as Inconel 625 fasteners in terms of their tensile strength.

Inconel 718 is renowned for its exceptional creep rupture strength at temperatures as high as 1300 degrees Fahrenheit or 700 degrees Celsius. Even though DIN 2.4668 stud bolts can resist elevated temperatures of up to 1800 degrees Fahrenheit or 982 degrees Celsius, it is possible. According to the standard described above for cold working Inconel 718, the alloy may have a tensile strength of no less than 220 ksi at its lowest point.

Types Of Inconel 718 Fasteners

Inconel 718 Fasteners Specification

| Specifications | ASTM B637 / ASME SB637 |

| Standard | DIN, ISO ,JIS ,GB, IS, BS, ASTM and all International Standards |

| Size | M3 - M100 | 3/6″ - 4″ | Custom Sizes |

| Fasteners Length | 3 mm - 200 mm | Custom Sizes |

| Nuts Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Washers Size | M3 - M56 | 3/6" to 2" | Custom Sizes |

| Dimensions | DIN 931, 933, 934, 7991, 976, 125, ASME B18.2.1, B18.3 |

| Threads available | UNF, BSW, BSF, METRIC, UNC, or as required |

| Threads Configuration | ASME B1.1 2A/3A – 2B/3B Inch Unified Threads and B1.13M 6h-6G Metric Coarse Threads |

| Form | Hex, Threading, Square, Round as per Gauge Etc. |

| Head | Hex, Square, Round, Hex flange, Flat, T-head & Triangular etc. |

| Neck type | Hex, Square, Triangular, Oval & Knurled etc. |

| Surface Treatment | Passivation /plain |

| Others Factor | OEM, ODM, ±0.03MM tolerance |

| Manufacturing Process | Wire Drawing, Cold Heading, Insert tapping, Heat Treatment, Surface Plating, Inspection, Packing. |

| Packing | IN BULK: carton, pallet, Small Boxes or customer request |

| Surface Coating | Black Oxide, Cadmium, Galvanized, Teflon, Xylan, Zinc, Others Upon Request |

| Test Certificate | As per EN 10204 / 3.1 Manufacturer Test Certificate, PED 97/23/EC Certified, Merkblatt AD 2000 W2 Certified |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Delivery time | Regular product : 7-15 days, Custom product : 2-4 weeks |

| Place of Origin | India |

Equivalent Grades Inconel 718 Fasteners

| STANDARD | WERKSTOFF NR. | UNS |

| Inconel 718 | 2.4668 | N07718 |

Chemical Composition Inconel 718 Fasteners

| Grade | C | Mn | Si | P | S | Ni | Cr | B | Mo | Co | Al | Ti | Nb | Cu |

| Inconel 718 | 0.08 max | 0.35 max | 0.35 max | 0.015 max | 0.015 max | 50 – 55 | 17 – 21 | 0.006 max | 2.8 – 3.3 | 1.0 max | 0.2 – 0.8 | 0.65 – 1.15 | 4.75 – 5.5 | 0.3 max |

Mechanical Properties Inconel 718 Fasteners

| Element | Density | Melting Point | Tensile Strength | Yield Strength (0.2%Offset) | Elongation |

| Inconel 718 | 8.2 g/cm3 | 1350 °C (2460 °F) | Psi – 1,35,000, MPa – 930 | Psi – 75,000, MPa – 482 | 45 % |

Dimensions Of Inconel 718 Fasteners

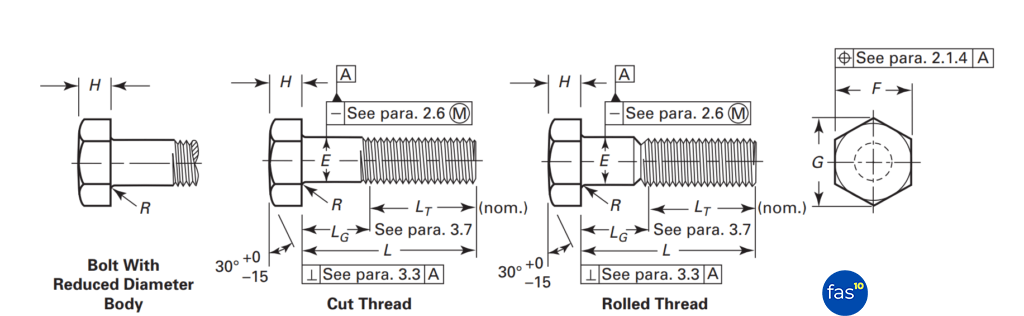

Inconel 718 Bolts Dimensions Chart :

| Nominal Size or Basic Product Diameter | Full-Size Body Diameter, E | Width Across Flats, F | Width Across Corners, G | Head Height, H Basic | Radius of Fillet, R | Nominal Thread Length for Bolt Lengths, LT |

|||||||||

| inch | mm | Max | Min | Basic inch | Max | Min | Max | Min | Basic inch | Max | Min | Max | Min | 6 in. and Shoter | Over 6 in. |

| 1⁄4 | 0.25 | 0.26 | 0.237 | 7⁄16 | 0.438 | 0.425 | 0.505 | 0.484 | 11⁄64 | 0.188 | 0.15 | 0.03 | 0.01 | 0.75 | 1 |

| 5⁄16 | 0.3125 | 0.324 | 0.298 | 1⁄2 | 0.5 | 0.484 | 0.577 | 0.552 | 7⁄32 | 0.235 | 0.195 | 0.03 | 0.01 | 0.875 | 1.125 |

| 3⁄8 | 0.375 | 0.388 | 0.36 | 9⁄16 | 0.562 | 0.544 | 0.65 | 0.62 | 1⁄4 | 0.268 | 0.226 | 0.03 | 0.01 | 1 | 1.25 |

| 7⁄16 | 0.4375 | 0.452 | 0.421 | 5⁄8 | 0.625 | 0.603 | 0.722 | 0.687 | 19⁄64 | 0.316 | 0.272 | 0.03 | 0.01 | 1.125 | 1.375 |

| 1⁄2 | 0.5 | 0.515 | 0.482 | 3⁄4 | 0.75 | 0.725 | 0.866 | 0.826 | 11⁄32 | 0.364 | 0.302 | 0.03 | 0.01 | 1.25 | 1.5 |

| 5⁄8 | 0.625 | 0.642 | 0.605 | 15⁄16 | 0.938 | 0.906 | 1.083 | 1.033 | 27⁄64 | 0.444 | 0.378 | 0.06 | 0.02 | 1.5 | 1.75 |

| 3⁄4 | 0.75 | 0.768 | 0.729 | 11⁄8 | 1.125 | 1.088 | 1.299 | 1.24 | 1⁄2 | 0.524 | 0.455 | 0.06 | 0.02 | 1.75 | 2 |

| 7⁄8 | 0.875 | 0.895 | 0.852 | 1 5⁄16 | 1.312 | 1.269 | 1.516 | 1.447 | 37⁄64 | 0.604 | 0.531 | 0.06 | 0.02 | 2 | 2.25 |

| 1 | 1 | 1.022 | 0.976 | 1 1⁄2 | 1.5 | 1.45 | 1.732 | 1.653 | 43⁄64 | 0.7 | 0.591 | 0.09 | 0.03 | 2.25 | 2.5 |

| 1 1⁄8 | 1.125 | 1.149 | 1.098 | 1 11⁄16 | 1.688 | 1.631 | 1.949 | 1.859 | 3⁄4 | 0.78 | 0.658 | 0.09 | 0.03 | 2.5 | 2.75 |

| 1 1⁄4 | 1.25 | 1.277 | 1.223 | 1 7⁄8 | 1.875 | 1.812 | 2.165 | 2.066 | 27⁄32 | 0.876 | 0.749 | 0.09 | 0.03 | 2.75 | 3 |

| 1 3⁄8 | 1.375 | 1.404 | 1.345 | 2 1⁄16 | 2.062 | 1.994 | 2.382 | 2.273 | 29⁄32 | 0.94 | 0.81 | 0.09 | 0.03 | 3 | 3.25 |

| 1 1⁄2 | 1.5 | 1.531 | 1.47 | 2 1⁄4 | 2.25 | 2.175 | 2.598 | 2.48 | 1 | 1.036 | 0.902 | 0.09 | 0.03 | 3.25 | 3.5 |

| 1 5⁄8 | 1.625 | 1.658 | 1.591 | 2 7⁄16 | 2.438 | 2.356 | 2.815 | 2.616 | 1 3⁄32 | 1.116 | 0.978 | 0.09 | 0.03 | 3.5 | 3.75 |

| 1 3⁄4 | 1.75 | 1.785 | 1.716 | 2 5⁄8 | 2.625 | 2.538 | 3.031 | 2.893 | 1 5⁄32 | 1.196 | 1.054 | 0.12 | 0.04 | 3.75 | 4 |

| 1 7⁄8 | 1.875 | 1.912 | 1.839 | 2 13⁄16 | 2.812 | 2.719 | 3.248 | 3.099 | 1 1⁄4 | 1.276 | 1.13 | 0.12 | 0.04 | 4 | 4.25 |

| 2 | 2 | 2.039 | 1.964 | 3 | 3 | 2.9 | 3.464 | 3.306 | 1 11⁄32 | 1.388 | 1.175 | 0.12 | 0.04 | 4.25 | 4.5 |

| 2 1⁄4 | 2.25 | 2.305 | 2.214 | 3 3⁄8 | 3.375 | 3.262 | 3.897 | 3.719 | 1 1⁄2 | 1.548 | 1.327 | 0.19 | 0.06 | 4.75 | 5 |

| 2 1⁄2 | 2.5 | 2.559 | 2.461 | 3 3⁄4 | 3.75 | 3.625 | 4.33 | 4.133 | 1 21⁄32 | 1.708 | 1.479 | 0.19 | 0.06 | 5.25 | 5.5 |

| 2 3⁄4 | 2.75 | 2.827 | 2.711 | 4 1⁄8 | 4.125 | 3.988 | 4.763 | 4.546 | 1 13⁄16 | 1.869 | 1.632 | 0.19 | 0.06 | 5.75 | 6 |

| 3 | 3 | 3.081 | 2.961 | 4 1⁄2 | 4.5 | 4.35 | 5.196 | 4.959 | 2 | 2.06 | 1.815 | 0.19 | 0.06 | 6.25 | 6.5 |

| 3 1⁄4 | 3.25 | 3.335 | 3.21 | 4 7⁄8 | 4.875 | 4.712 | 5.629 | 5.372 | 2 3⁄16 | 2.251 | 1.936 | 0.19 | 0.06 | 6.75 | 7 |

| 3 1⁄2 | 3.5 | 3.589 | 3.461 | 5 1⁄4 | 5.25 | 5.075 | 6.062 | 5.786 | 2 5⁄16 | 2.38 | 2.057 | 0.19 | 0.06 | 7.25 | 7.5 |

| 3 3⁄4 | 3.75 | 3.858 | 3.726 | 5 5⁄8 | 5.625 | 5.437 | 6.495 | 6.198 | 2 1⁄2 | 2.572 | 2.241 | 0.19 | 0.06 | 7.75 | 8 |

| 4 | 4 | 4.111 | 3.975 | 6 | 6 | 5.8 | 6.928 | 6.612 | 2 11⁄16 | 2.764 | 2.424 | 0.19 | 0.06 | 8.25 | 8.5 |

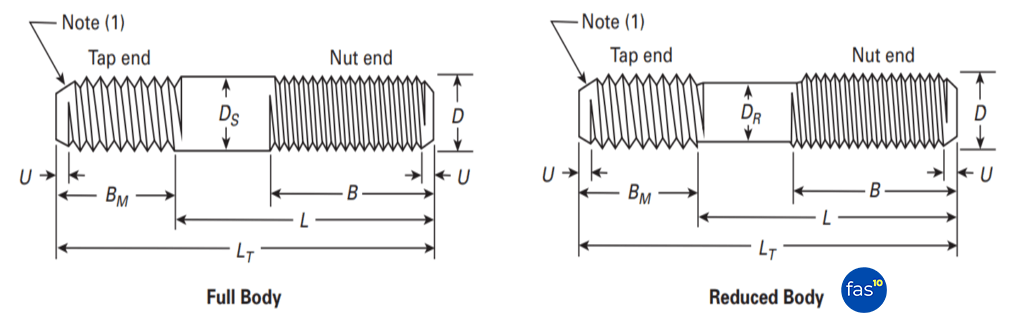

Inconel 718 Stud Bolts Dimensions Chart :

| Nominal Size Diameter, D inch | Tap End Full Thread Length, BM | Umax = 2P | Minimum Nut End Full Thread Length, Bmin |

||||||

| Nominal | Min. | Max. | UNC & NC-5 Thread | UNF Thread | 8UN Thread | L ≤ 10 | 10 < L ≤ 16 | L > 16 | |

| 1/4 | 0.375 | 0.350 | 0.400 | 0.100 | 0.071 | ... | 0.750 | 1.000 | 1.500 |

| 5/16 | 0.469 | 0.440 | 0.498 | 0.111 | 0.083 | -- | 0.875 | 1.125 | 1.625 |

| 3/8 | 0.563 | 0.532 | 0.594 | 0.125 | 0.083 | -- | 1.000 | 1.250 | 1.750 |

| 7/16 | 0.656 | 0.620 | 0.692 | 0.143 | 0.100 | -- | 1.125 | 1.375 | 1.875 |

| 1/2 | 0.750 | 0.708 | 0.792 | 0.154 | 0.100 | -- | 1.250 | 1.500 | 2.000 |

| 9/16 | 0.844 | 0.802 | 0.896 | 0.167 | 0.111 | -- | 1.375 | 1.625 | 2.125 |

| 5/8 | 0.938 | 0.892 | 0.983 | 0.182 | 0.111 | -- | 1.500 | 1.750 | 2.250 |

| 3/4 | 1.1.25 | 1.075 | 1.175 | 0.200 | 0.125 | -- | 1.750 | 2.000 | 2.500 |

| 7/8 | 1.313 | 1.258 | 1.368 | 0.222 | 0.143 | -- | 2.000 | 2.250 | 2.750 |

| 1 | 1.500 | 1.438 | 1.562 | 0.250 | 0.167 | -- | 2.250 | 2.500 | 3.000 |

| 1 1/8 | 1.688 | 1.625 | 1.750 | 0.286 | 0.167 | 0.250 | 2.500 | 2.750 | 3.250 |

| 1 1/4 | 1.875 | 1.813 | 1.938 | 0.286 | 0.167 | 0.250 | 2.750 | 3.000 | 3.500 |

| 1 3/8 | 2.063 | 2.000 | 2.125 | 0.333 | 0.167 | 0.250 | 3.000 | 3.250 | 3.750 |

| 1 1/2 | 2.250 | 2.188 | 2.313 | 0.333 | 0.167 | 0.250 | 3.250 | 3.500 | 4.000 |

| 1 5/8 | 2.438 | 2.375 | 2.500 | -- | -- | 0.250 | 3.500 | 3.750 | 4.250 |

| 1 3/4 | 2.625 | 2.563 | 2.688 | 0.400 | -- | 0.250 | 3.750 | 4.000 | 4.500 |

| 1 7/8 | 2.813 | 2.750 | 2.875 | -- | -- | 0.250 | 4.000 | 4.250 | 4.750 |

| 2 | 3.000 | 2.925 | 3.075 | 0.444 | -- | 0.250 | 4.250 | 4.500 | 5.000 |

| 2 1/4 | 3.375 | 3.300 | 3.450 | 0.444 | -- | 0.250 | 4.750 | 5.000 | 5.500 |

| 2 1/2 | 3.750 | 3.675 | 3.825 | 0.500 | -- | 0.250 | 5.250 | 5.500 | 6.000 |

| 2 3/4 | 4.125 | 4.050 | 4.200 | 0.500 | -- | 0.250 | 5.750 | 6.000 | 6.500 |

| 3 | 4.500 | 4.425 | 4.575 | 0.500 | -- | 0.250 | -- | 6.500 | 7.000 |

| 3 1/4 | 4.875 | 4.775 | 4.975 | 0.500 | -- | 0.250 | -- | 7.000 | 7.500 |

| 3 1/2 | 5.250 | 5.150 | 5.350 | 0.500 | -- | 0.250 | -- | 7.500 | 8.000 |

| 3 3/4 | 5.625 | 5.525 | 5.725 | 0.500 | -- | 0.250 | -- | 8.000 | 8.500 |

| 4 | 6.000 | 5.900 | 6.100 | 0.500 | -- | 0.250 | -- | 8.500 | 9.000 |

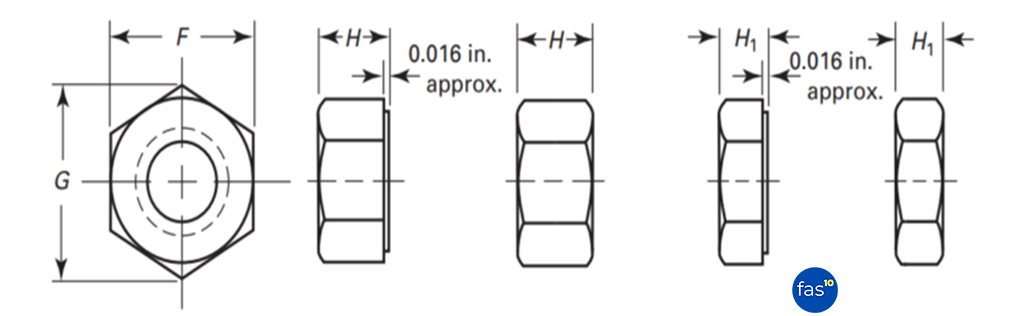

Inconel 718 Nuts Dimensions :

| Nominal Size inch | Basic Major Diameter of Thread | Width Across Flats, F | Width Across Corners, G | Thickness Heavy Hex Nuts, H | Thickness Heavy Hex Jam Nuts, H1 | Maximum Runout of Bearing Surface to Thread Axis, FIM |

|||||||||

| Heavy HEX NUTS | Heavy Hex Jam Nuts |

||||||||||||||

| Specified Proof load | |||||||||||||||

| Basic inch | Min. | Max | Min. | Max | Basic inch | Min. | Max | Basic inch | Min. | Max | Up to 150,000 psi | 150,000 psi and Greater | All Strength Levels |

||

| 1/4 | 0.2500 | 1/2 | 0.488 | 0.500 | 0.556 | 0.577 | 15/64 | 0.218 | 0.250 | 11/64 | 0.156 | 0.188 | 0.017 | 0.011 | 0.017 |

| 5/16 | 0.3125 | 9/16 | 0.546 | 0.562 | 0.622 | 0.650 | 19/64 | 0.280 | 0.314 | 13/64 | 0.186 | 0.220 | 0.020 | 0.012 | 0.020 |

| 3/8 | 0.3750 | 11/16 | 0.669 | 0.688 | 0.763 | 0.794 | 23/64 | 0.341 | 0.377 | 15/64 | 0.216 | 0.252 | 0.021 | 0.014 | 0.021 |

| 7/16 | 0.4375 | 3/4 | 0.728 | 0.750 | 0.830 | 0.866 | 27/64 | 0.403 | 0.441 | 17/64 | 0.247 | 0.285 | 0.022 | 0.015 | 0.022 |

| 1/2 | 0.5000 | 7/8 | 0.850 | 0.875 | 0.969 | 1.010 | 31/64 | 0.464 | 0.504 | 19/64 | 0.277 | 0.317 | 0.023 | 0.016 | 0.023 |

| 9/16 | 0.5625 | 15/16 | 0.909 | 0.938 | 1.037 | 1.083 | 35/64 | 0.526 | 0.568 | 21/64 | 0.307 | 0.349 | 0.024 | 0.017 | 0.024 |

| 5/8 | 0.6250 | 1 1/16 | 1.031 | 1.062 | 1.175 | 1.227 | 39/64 | 0.587 | 0.631 | 23/64 | 0.337 | 0.381 | 0.025 | 0.018 | 0.025 |

| 3/4 | 0.7500 | 1 1/4 | 1.212 | 1.250 | 1.382 | 1.443 | 47/64 | 0.710 | 0.758 | 27/64 | 0.398 | 0.446 | 0.027 | 0.020 | 0.027 |

| 7/8 | 0.8750 | 1 7/16 | 1.394 | 1.438 | 1.589 | 1.660 | 55/64 | 0.833 | 0.885 | 31/64 | 0.458 | 0.510 | 0.029 | 0.022 | 0.029 |

| 1 | 1.0000 | 1 5/8 | 1.575 | 1.625 | 1.796 | 1.876 | 63/64 | 0.956 | 1.012 | 35/64 | 0.519 | 0.575 | 0.031 | 0.024 | 0.031 |

| 1 1/8 | 1.1250 | 1 13/16 | 1.756 | 1.812 | 2.002 | 2.093 | 1 7/64 | 1.079 | 1.139 | 39/64 | 0.579 | 0.639 | 0.033 | 0.027 | 0.033 |

| 1 1/4 | 1.2500 | 2 | 1.938 | 2.000 | 2.209 | 2.309 | 1 7/32 | 1.187 | 1.251 | 23/32 | 0.687 | 0.751 | 0.035 | 0.030 | 0.035 |

| 1 3/8 | 1.3750 | 2 3/16 | 2.119 | 2.188 | 2.416 | 2.526 | 1 11/32 | 1.310 | 1.378 | 25/32 | 0.747 | 0.815 | 0.038 | 0.033 | 0.038 |

| 1 1/2 | 1.5000 | 2 3/8 | 2.300 | 2.375 | 2.622 | 2.742 | 1 15/32 | 1.433 | 1.505 | 27/32 | 0.808 | 0.880 | 0.041 | 0.036 | 0.041 |

| 1 5/8 | 1.6250 | 2 9/16 | 2.481 | 2.562 | 2.828 | 2.959 | 1 19/32 | 1.556 | 1.632 | 29/32 | 0.868 | 0.944 | 0.044 | 0.038 | 0.044 |

| 1 3/4 | 1.7500 | 2 3/4 | 2.662 | 2.750 | 3.035 | 3.175 | 1 23/32 | 1.679 | 1.759 | 31/32 | 0.929 | 1.009 | 0.048 | 0.041 | 0.048 |

| 1 7/8 | 1.8750 | 2 15/16 | 2.844 | 2.938 | 3.242 | 3.392 | 1 27/32 | 1.802 | 1.886 | 1 1/32 | 0.989 | 1.073 | 0.051 | 0.044 | 0.051 |

| 2 | 2.0000 | 3 1/8 | 3.025 | 3.125 | 3.449 | 3.608 | 1 31/32 | 1.925 | 2.013 | 1 3/32 | 1.050 | 1.138 | 0.055 | 0.047 | 0.055 |

| 2 1/4 | 2.2500 | 3 1/2 | 3.388 | 3.500 | 3.862 | 4.041 | 2 13/64 | 2.155 | 2.251 | 1 13/64 | 1.155 | 1.251 | 0.061 | 0.052 | 0.061 |

| 2 1/2 | 2.5000 | 3 7/8 | 3.750 | 3.875 | 4.275 | 4.474 | 2 29/64 | 2.401 | 2.505 | 1 29/64 | 1.401 | 1.505 | 0.068 | 0.058 | 0.068 |

| 2 3/4 | 2.7500 | 4 1/4 | 4.112 | 4.250 | 4.688 | 4.907 | 2 45/64 | 2.647 | 2.759 | 1 37/64 | 1.522 | 1.634 | 0.074 | 0.064 | 0.074 |

| 3 | 3.0000 | 4 5/8 | 4.475 | 4.625 | 5.102 | 5.340 | 2 61/64 | 2.893 | 3.013 | 1 45/64 | 1.643 | 1.763 | 0.081 | 0.070 | 0.081 |

| 3 1/4 | 3.2500 | 5 | 4.838 | 5.000 | 5.515 | 5.774 | 3 3/16 | 3.124 | 3.252 | 1 13/16 | 1.748 | 1.876 | 0.087 | 0.075 | 0.087 |

| 3 1/2 | 3.5000 | 5 3/8 | 5.200 | 5.375 | 5.928 | 6.207 | 3 7/16 | 3.370 | 3.506 | 1 15/16 | 1.870 | 2.006 | 0.094 | 0.081 | 0.094 |

| 3 3/4 | 3.7500 | 5 3/4 | 5.562 | 5.750 | 6.341 | 6.640 | 3 11/16 | 3.616 | 3.760 | 2 1/16 | 1.990 | 2.134 | 0.100 | 0.087 | 0.100 |

| 4 | 4.0000 | 6 1/8 | 5.925 | 6.125 | 6.755 | 7.073 | 3 15/16 | 3.862 | 4.014 | 2 3/16 | 2.112 | 2.264 | 0.107 | 0.093 | 0.107 |

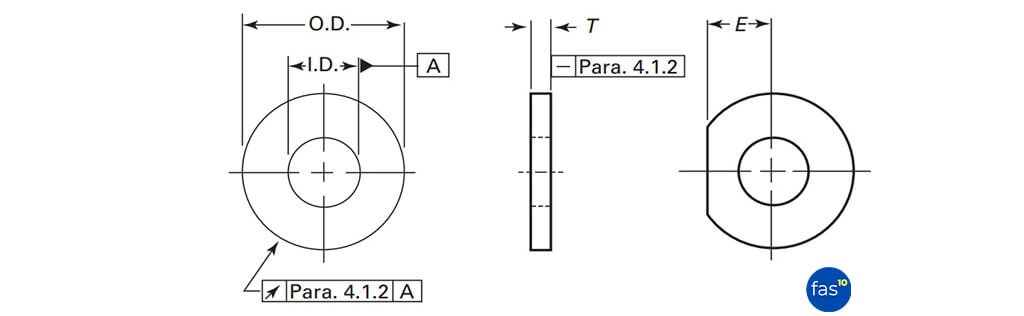

Inconel 718 Washer Dimensions Chart :

| Nominal Size | T | Clipped Width E, Min. | ||||||||||||

| I.D. | O.D. | Standard | Extra Thick | |||||||||||

| [Note (1)] | Max. | Min. | Max. | Min. | Max. | Min. | Max. | Min. | [Note (2)] | |||||

| 12 | 14.4 | 14 | 27 | 25.7 | 4.6 | 3.1 | 10 | 8 | 10.5 | |||||

| 16 | 18.4 | 18 | 34 | 32.4 | 4.6 | 3.1 | 10 | 8 | 14 | |||||

| 20 | 22.5 | 22 | 42 | 40.4 | 4.6 | 3.1 | 10 | 8 | 17.5 | |||||

| 22 | 24.5 | 24 | 44 | 42.4 | 4.6 | 3.4 | 10 | 8 | 19.2 | |||||

| 24 | 26.5 | 26 | 50 | 48.4 | 4.6 | 3.4 | 10 | 8 | 21 | |||||

| 27 | 30.5 | 30 | 56 | S4.1 | 4.6 | 3.4 | 10 | 8 | 23.6 | |||||

| 30 | 33.6 | 33 | 60 | 58.1 | 4.6 | 3.4 | 10 | 8 | 26.2 | |||||

| 36 | 39.6 | 39 | 72 | 70.1 | 4.6 | 3.4 | 10 | 8 | 31.S | |||||

| 42 | 45.6 | 45 | 84 | 81.8 | 7.2 | 4.6 | 10 | 8 | 36.7 | |||||

| 48 | 52.7 | 52 | 95 | 92.8 | 7.2 | 4.6 | 10 | 8 | 42 | |||||

| 56 | 62.7 | 62 | 107 | 104.8 | 8.7 | 6.1 | 10 | 8 | 49 | |||||

| 64 | 70.7 | 70 | 118 | 115.8 | 8.7 | 6.1 | 10 | 8 | 56 | |||||

| 72 | 78.7 | 78 | 130 | 127.5 | 8.7 | 6.1 | 10 | 8 | 63 | |||||

| 80 | 86.9 | 86 | 142 | 139.5 | 8.7 | 6.1 | 10 | 8 | 70 | |||||

| 90 | 96.9 | 96 | 159 | 156.5 | 8.7 | 6.1 | 10 | 8 | 78.7 | |||||

| 100 | 107.9 | 107 | 176 | 173.5 | 8.7 | 6.1 | 10 | 8 | 87.5 | |||||

Different Types Of Inconel 718 Fasteners

Different Types Of Bolts:

ASTM B564 Inconel 718 Hex Bolts

DIN 2.4668 Carriage Bolts

Inconel 718 Stud Bolts

UNS N07718 Hex Head Bolts

Inconel 718 Forged Hook Bolts

DIN 2.4668 Torx Bolts

Inconel 718 Countersunk Bolts

DIN 2.4668 Flange Head Bolts

UNS N07718 Allen Bolts

N07718 UNS 12-Point Flange Bolts

ASTM B564 UNS N07718 Eye Bolts

DIN 2.4668 Bolts

AISI Inconel 718 U Bolts

Inconel 718 J Bolts

UNS N07718 Elevator Bolt

ASTM B564 Grade 718 Threaded Expansion Anchor Bolt

ASME SB 564 Inconel 718 High Performance Anchor Bolts

UNS N07718 Lag Bolts

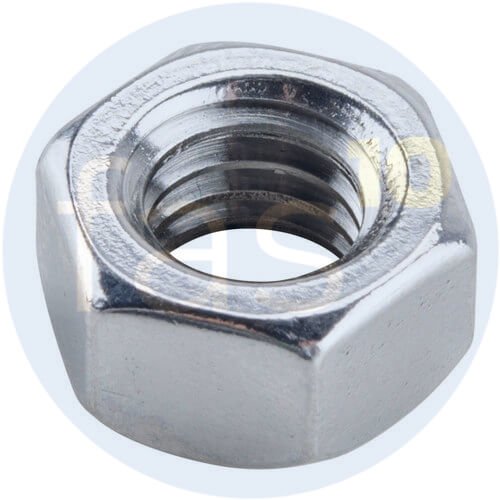

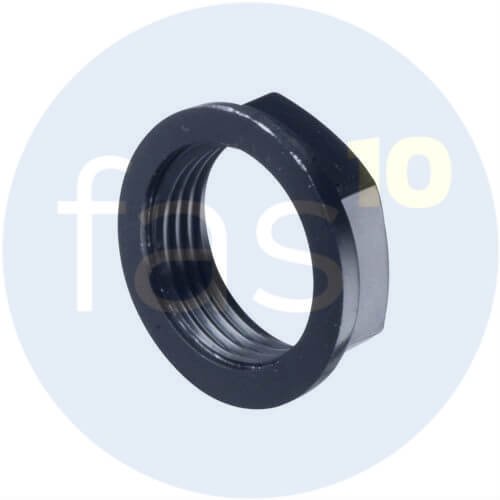

Different Types Of Nuts:

ASTM B564 Inconel 718 Hex Nuts

ASME SB564 Inconel 718 T Nuts

Inconel 718 Metric Nuts

UNS N07718 Rivet Nuts

718 Inconel Sleeve Nuts

718 Inconel 12-Point Nuts

ASTM B564 Grade 718 Lug Nut

DIN 2.4668 Captive Nuts

Inconel 718 Dome Nuts

ASME SB 564 Inconel 718 Acorn Nuts

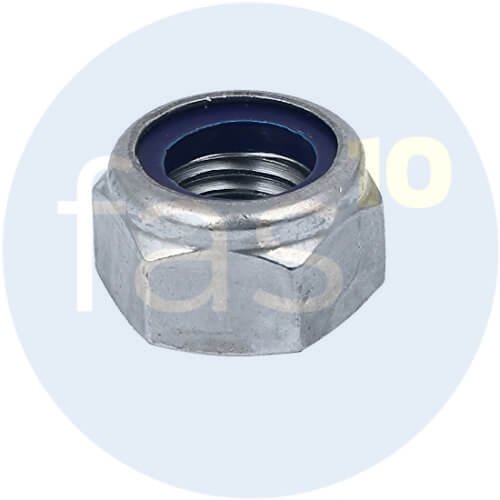

Inconel 718 Nyloc Nuts

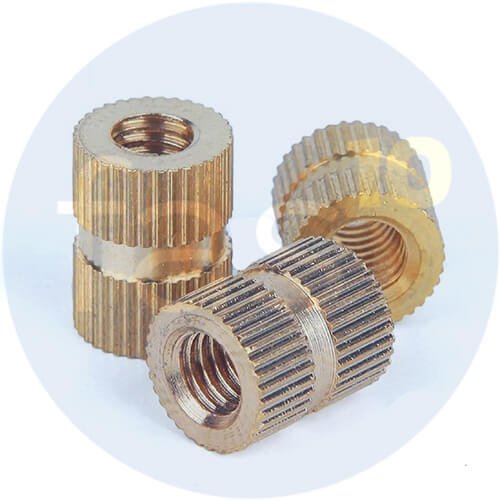

UNS N07718 Insert Nuts

718 Inconel Lock Nuts

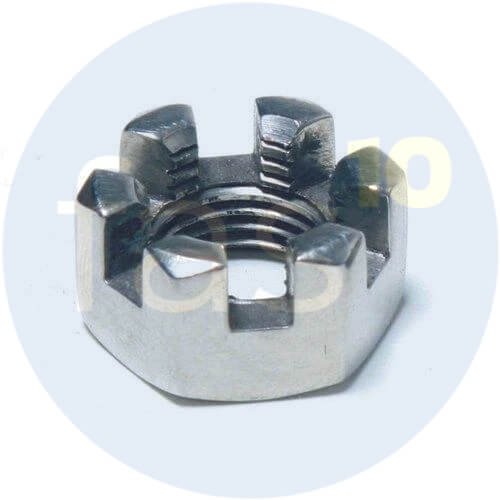

ASTM B564 UNS N07718 Castle Nuts

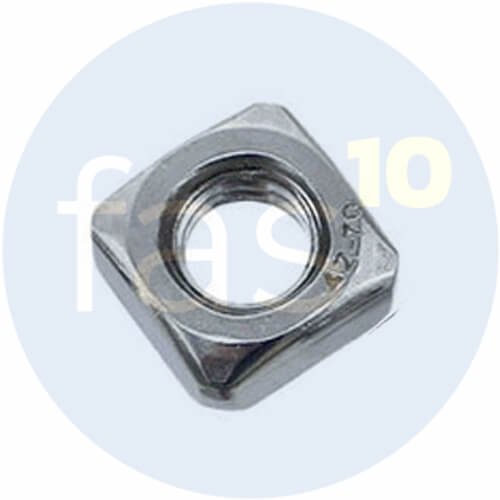

AISI 718 Square Nuts

Different Types Of Washers:

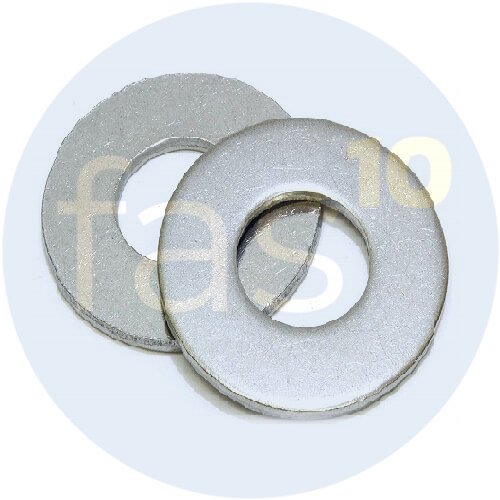

ASTM B564 Inconel 718 Plain Washer

ASME SB564 Inconel 718 Tab Washer

Inconel 718 Spring Washer

UNS N07718 Sealing Washer

Inconel 718 Lock Washer

UNS N07718 Square Washer

ASTM B564 Grade 718 Flat Washer

DIN 2.4668 Split Washer

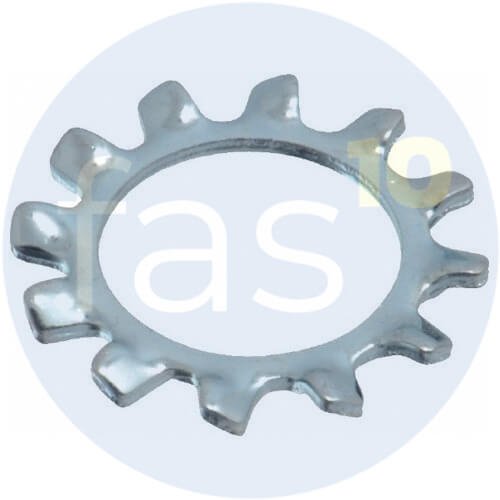

Inconel 718 Star Washer

Different Types Of Screw:

ASTM B564 Inconel 718 Torx Screws

Inconel 718 Self Drilling Screws

DIN 2.4668 Grub Screws

ASME SB564 Inconel 718 Countersunk Screws

Inconel 718 Self Tapping

Screws

ASTM B564 Grade 718

Wood Screws