ASTM A320 Bolt

Grade A320 Flange Head Bolt, ASTM A320 B8 Hex Head Bolt, ASME SA320 Grade L7 U Bolt, Grade B8M Allen Bolt, A320 Grade Stud Bolt, ASME SA320 Grade Eye Bolt.

Bolts built to ASTM A320 specifications for stainless and alloy steel are designed for the least-level temperature applications. It includes fasteners that are forged and strain-hardened rolled. The largest manufacturer of ASTM A320 Bolt is fas10. A320’s specification includes class 2, followed by class 1, as well as the L43, L7, B8, and B8M. These are additionally quenched, tempered, treated with a carbide solution, and strain-hardened. ¾ – 2 ½ inches is the size range.

Different yield tensile strengths are included in the ASTM A320 L7 Stud Bolts. Depending on the various grades within the A320 specification, the required tensile strength ranges from 75 ksi to 125 ksi. The necessary yield strengths for the a320 bolts range from 30 ksi to 105 ksi, and their elongation ratios/rates range from 12% to 30%. The grades’ material compositions differ in terms of sulfur, chromium, silicon, manganese, nickel, molybdenum, phosphorus, and carbon. The nickel content of 14%, Chromium content of 18%, and molybdenum content of 3% are all present in the ASTM A320 l7M Nuts. The A320 fasteners are robust, malleable, and corrosion-resistant, all because of these material compositions.

About ASTM A320 Bolt

ASTM A320 L7M Hex Bolt, SA320 Grade B8 Allen Bolt, Grade A320 Hex Head Bolt, ASME SA320 Grade L7M Anchor Bolt, Grade B8M U Bolt, ASTM A320 Flange Head Bolt.

Various applications call for the use of ASTM A320 stainless steel bolts. Uses for heat exchangers, boilers, and condensers include power generation facilities, food processing facilities, oil and gas heavy industries, and petroleum, maritime, chemicals, and pharmaceuticals. As a top manufacturer of Grade B8M Allen Bolt, we provide other bolts in various dimensions. For further information and a quote on fasteners that meet the requirements of the A320, don’t hesitate to contact us.

ASTM A320 Bolt Specification

| Dimensions | ASME B18.2.1, B18.3 |

| Melt Origin | Korea, South America, Japan, East Europe, |

| Mandatory Requirements | Free from Mercury & Radioactive Contamination |

| Additional Certifications | PED 97/ 23/ EC Certified, Merkblatt AD 2000 W2 Certified |

| Certification | Dual Certified As per ASTM & ASME Codes |

| Additional Requirements | NACE MR0103 / MR0175 / ISO 15156 Compliance |

| Threads Configuration | ASME B1.1 2A/3A Inch Unified Threads and B1.13M 6h Metric Coarse Threads |

Chemical Composition ASTM A320 Bolt

| Element | L7 (AISI 4140) | L43 (AISI 4340) | B8 (AISI 304) | B8M (AISI 316) |

| Carbon | 0.37 – 0.49% | 0.38 – 0.43% | 0.08% max | 0.08% max |

| Manganese | 0.65 – 1.10% | 0.75 – 1.00% | 2.00% max | 2.00% max |

| Phosphorus (max) | 0.04% | 0.04% | 0.05% | 0.05% |

| Sulfur (max) | 0.04% | 0.04% | 0.03% | 0.03% |

| Silicon | 0.15 – 0.35% | 0.15 – 0.35% | 1.00% max | 1.00% max |

| Chromium | 0.75 – 1.20% | 0.70 – 0.90% | 18.0 – 20.0% | 16.0 – 18.0% |

| Nickel | 1.65 – 2.00% | 8.0 – 11.0% | 10.0 – 14.0% | |

| Molybdenum | 0.15 – 0.25% | 0.20 – 0.30% | 2.00 – 3.00% |

Mechanical Properties ASTM A320 Bolt

| Grade | Size | Tensile, ksi min | Yield, ksi min | Charpy Impact | Elong, % min | RA, %, min |

| L7 | up to 21/2 | 125 | 105 | -150° F | 16 | 50 |

| L43 | sup a 4 | 125 | 105 | -150° F | 16 | 50 |

| B8 Class 1 | all | 75 | 30 | N/A | 30 | 50 |

| B8M Class 1 | all | 75 | 30 | N/A | 30 | 50 |

| B8 Class 2 | Up to 3/4 | 125 | 100 | N/A | 12 | 35 |

| 7/8 – 1 | 115 | 80 | N/A | 15 | 35 | |

| 11/8 – 11/4 | 105 | 65 | N/A | 20 | 35 | |

| 13/8 – 11/2 | 100 | 50 | N/A | 28 | 45 | |

| B8M Class 2 | Up to 3/4 | 110 | 95 | N/A | 15 | 45 |

| 7/8 – 1 | 100 | 80 | N/A | 20 | 45 | |

| 11/8 – 11/4 | 95 | 65 | N/A | 25 | 45 | |

| 13/8 – 11/2 | 90 | 50 | N/A |

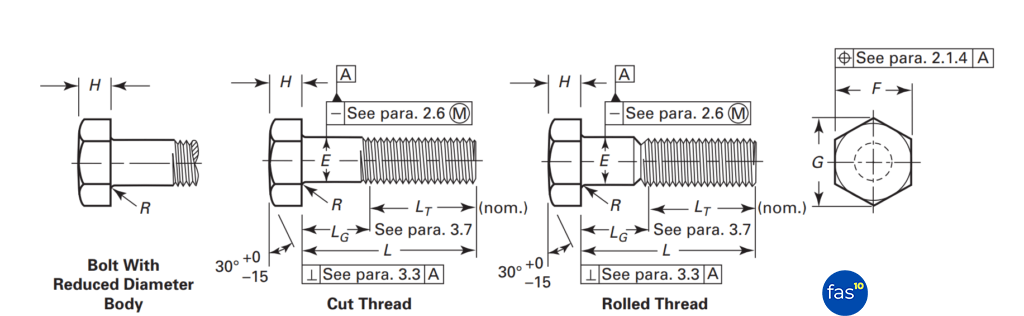

Dimensions Of ASTM A320 Bolt

ASTM A320 Bolts Dimensions Chart :

| Nominal Size or Basic Product Diameter | Full-Size Body Diameter, E | Width Across Flats, F | Width Across Corners, G | Head Height, H Basic | Radius of Fillet, R | Nominal Thread Length for Bolt Lengths, LT |

|||||||||

| inch | mm | Max | Min | Basic inch | Max | Min | Max | Min | Basic inch | Max | Min | Max | Min | 6 in. and Shoter | Over 6 in. |

| 1⁄4 | 0.25 | 0.26 | 0.237 | 7⁄16 | 0.438 | 0.425 | 0.505 | 0.484 | 11⁄64 | 0.188 | 0.15 | 0.03 | 0.01 | 0.75 | 1 |

| 5⁄16 | 0.3125 | 0.324 | 0.298 | 1⁄2 | 0.5 | 0.484 | 0.577 | 0.552 | 7⁄32 | 0.235 | 0.195 | 0.03 | 0.01 | 0.875 | 1.125 |

| 3⁄8 | 0.375 | 0.388 | 0.36 | 9⁄16 | 0.562 | 0.544 | 0.65 | 0.62 | 1⁄4 | 0.268 | 0.226 | 0.03 | 0.01 | 1 | 1.25 |

| 7⁄16 | 0.4375 | 0.452 | 0.421 | 5⁄8 | 0.625 | 0.603 | 0.722 | 0.687 | 19⁄64 | 0.316 | 0.272 | 0.03 | 0.01 | 1.125 | 1.375 |

| 1⁄2 | 0.5 | 0.515 | 0.482 | 3⁄4 | 0.75 | 0.725 | 0.866 | 0.826 | 11⁄32 | 0.364 | 0.302 | 0.03 | 0.01 | 1.25 | 1.5 |

| 5⁄8 | 0.625 | 0.642 | 0.605 | 15⁄16 | 0.938 | 0.906 | 1.083 | 1.033 | 27⁄64 | 0.444 | 0.378 | 0.06 | 0.02 | 1.5 | 1.75 |

| 3⁄4 | 0.75 | 0.768 | 0.729 | 11⁄8 | 1.125 | 1.088 | 1.299 | 1.24 | 1⁄2 | 0.524 | 0.455 | 0.06 | 0.02 | 1.75 | 2 |

| 7⁄8 | 0.875 | 0.895 | 0.852 | 1 5⁄16 | 1.312 | 1.269 | 1.516 | 1.447 | 37⁄64 | 0.604 | 0.531 | 0.06 | 0.02 | 2 | 2.25 |

| 1 | 1 | 1.022 | 0.976 | 1 1⁄2 | 1.5 | 1.45 | 1.732 | 1.653 | 43⁄64 | 0.7 | 0.591 | 0.09 | 0.03 | 2.25 | 2.5 |

| 1 1⁄8 | 1.125 | 1.149 | 1.098 | 1 11⁄16 | 1.688 | 1.631 | 1.949 | 1.859 | 3⁄4 | 0.78 | 0.658 | 0.09 | 0.03 | 2.5 | 2.75 |

| 1 1⁄4 | 1.25 | 1.277 | 1.223 | 1 7⁄8 | 1.875 | 1.812 | 2.165 | 2.066 | 27⁄32 | 0.876 | 0.749 | 0.09 | 0.03 | 2.75 | 3 |

| 1 3⁄8 | 1.375 | 1.404 | 1.345 | 2 1⁄16 | 2.062 | 1.994 | 2.382 | 2.273 | 29⁄32 | 0.94 | 0.81 | 0.09 | 0.03 | 3 | 3.25 |

| 1 1⁄2 | 1.5 | 1.531 | 1.47 | 2 1⁄4 | 2.25 | 2.175 | 2.598 | 2.48 | 1 | 1.036 | 0.902 | 0.09 | 0.03 | 3.25 | 3.5 |

| 1 5⁄8 | 1.625 | 1.658 | 1.591 | 2 7⁄16 | 2.438 | 2.356 | 2.815 | 2.616 | 1 3⁄32 | 1.116 | 0.978 | 0.09 | 0.03 | 3.5 | 3.75 |

| 1 3⁄4 | 1.75 | 1.785 | 1.716 | 2 5⁄8 | 2.625 | 2.538 | 3.031 | 2.893 | 1 5⁄32 | 1.196 | 1.054 | 0.12 | 0.04 | 3.75 | 4 |

| 1 7⁄8 | 1.875 | 1.912 | 1.839 | 2 13⁄16 | 2.812 | 2.719 | 3.248 | 3.099 | 1 1⁄4 | 1.276 | 1.13 | 0.12 | 0.04 | 4 | 4.25 |

| 2 | 2 | 2.039 | 1.964 | 3 | 3 | 2.9 | 3.464 | 3.306 | 1 11⁄32 | 1.388 | 1.175 | 0.12 | 0.04 | 4.25 | 4.5 |

| 2 1⁄4 | 2.25 | 2.305 | 2.214 | 3 3⁄8 | 3.375 | 3.262 | 3.897 | 3.719 | 1 1⁄2 | 1.548 | 1.327 | 0.19 | 0.06 | 4.75 | 5 |

| 2 1⁄2 | 2.5 | 2.559 | 2.461 | 3 3⁄4 | 3.75 | 3.625 | 4.33 | 4.133 | 1 21⁄32 | 1.708 | 1.479 | 0.19 | 0.06 | 5.25 | 5.5 |

| 2 3⁄4 | 2.75 | 2.827 | 2.711 | 4 1⁄8 | 4.125 | 3.988 | 4.763 | 4.546 | 1 13⁄16 | 1.869 | 1.632 | 0.19 | 0.06 | 5.75 | 6 |

| 3 | 3 | 3.081 | 2.961 | 4 1⁄2 | 4.5 | 4.35 | 5.196 | 4.959 | 2 | 2.06 | 1.815 | 0.19 | 0.06 | 6.25 | 6.5 |

| 3 1⁄4 | 3.25 | 3.335 | 3.21 | 4 7⁄8 | 4.875 | 4.712 | 5.629 | 5.372 | 2 3⁄16 | 2.251 | 1.936 | 0.19 | 0.06 | 6.75 | 7 |

| 3 1⁄2 | 3.5 | 3.589 | 3.461 | 5 1⁄4 | 5.25 | 5.075 | 6.062 | 5.786 | 2 5⁄16 | 2.38 | 2.057 | 0.19 | 0.06 | 7.25 | 7.5 |

| 3 3⁄4 | 3.75 | 3.858 | 3.726 | 5 5⁄8 | 5.625 | 5.437 | 6.495 | 6.198 | 2 1⁄2 | 2.572 | 2.241 | 0.19 | 0.06 | 7.75 | 8 |

| 4 | 4 | 4.111 | 3.975 | 6 | 6 | 5.8 | 6.928 | 6.612 | 2 11⁄16 | 2.764 | 2.424 | 0.19 | 0.06 | 8.25 | 8.5 |

Different Types Of ASTM A320 Bolt

Different Types Of Bolts:

ASTM A320 Hex Bolts

ASTM A320 Carriage Bolts

ASTM A320 Stud Bolts

ASTM A320 Hex Head Bolts

ASTM A320 Forged Hook Bolts

ASTM A320 Torx Bolts

ASTM A320 Countersunk Bolts

ASTM A320 Flange Head Bolts

ASTM A320 Allen Bolts

ASTM A320 12-Point Flange Bolts

ASTM A320 Eye Bolts

ASTM A320 Bolts

ASTM A320 U Bolts

ASTM A320 J Bolts

ASTM A320 Elevator Bolt

ASTM A320 Threaded Expansion Anchor Bolt

ASME SA320 High Performance Anchor Bolts